In post shredder material handling processes, it is of great importance to size the material in different fractions by means of screens. It is easily comprehensible that – after being crushed or shredded – the infeed material should be treated in several size fraction to get better sorting results.

The reason is that sensor based sorting machines have a much better efficiency if the infeed material is well classified and prepared. Thus, the material pieces must be distributed as perfectly as possible before passing the sensor system. Equally, the ejection module will be capable of extracting each particle piece separately. This is only possible if each material piece is laying completely free from any other material piece. It can be said that the performance of the sorting machine is highly dependent on the way the material is fed into the sorting system.

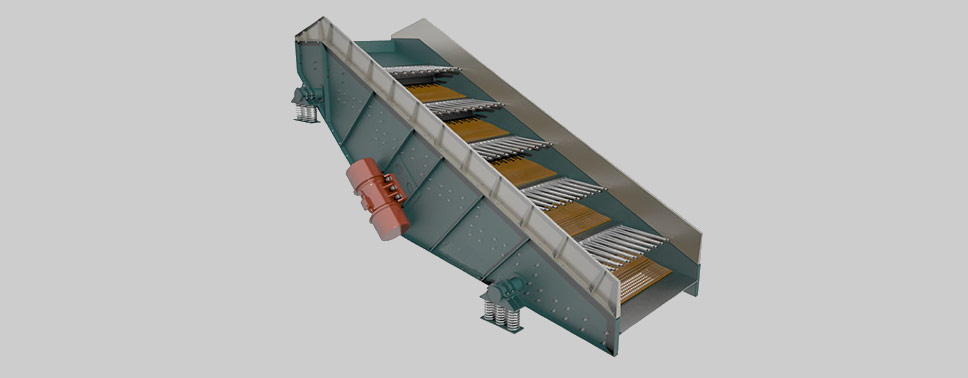

– the shredded bulk material has to be screened into different size fractions which we advise according to material type and sorting task

– each material size fraction will be processed separately in the sorting line

– the hopper and feeder make sure the bulk material pieces are fed optimally onto the conveyor belt

– if required, the bulk material can be treated with our Dust Buster dust suppression systems

Due to the great importance of material pre treatment, Toratecnica offers a superb choice of peripheral equipment to our customers. We take our proud in delivering the best and most efficient state-of-the-art sorting process technology available today using our many decades of experiences.