January 29, 2021

In connection with the aluminum shredder fraction, one speaks of aluminum production waste and recycled mixed aluminum (Zorba) post ECS. In this report we consider the suitability of the XRT and XRF technologies in aluminum sorting and the differences between the two X-ray based sorting technologies, namely XRF (X-Ray Fluorescence) and XRT (X-Ray Transmission). These technologies do not have high resolutions. To calculate the dimensions of a particle, i.e. shape and size, an additional sensor is often required with XRF. XRT (X-Ray Transmission) is based on the detection of different materials by means of the atomic particle density. Heavy metals are shown dark and light metals or organic materials are shown brighter or indistinct in the original images from the XRT sensor. For the use of XRT technology for sorting recycle enabled aluminum, the machine software is created according to the findings of the processor so that certain material is displayed in specific colors. For example, choose light gray or white for aluminum, red for copper, yellow for brass, blue for zinc, green for stainless steel and black for lead. In this way, recognition and display for sorting is easily possible. But what's the catch? The density of the material affects the permeability of the X-ray beam. It requires a greater force of radiation to penetrate dense material than soft material. The number of molecules per volume unit is decisive for the density of a material. Penetrating wood takes much less force than penetrating heavy metal. It is easier to penetrate plastic than aluminum or magnesium. The volume also plays an important role in the penetration of a material and the associated image that the software displays on the monitor. A large piece of plastic is represented identically to a smaller piece of aluminum. Or: a large piece of aluminum is represented identically as a thin piece of zinc with the same surface. Solutions to this challenge have been found over the course of time and with further developments in technology. However, it remains difficult and even mostly impossible to effectively sort aluminum production waste with XRT. Sorting sometimes also means compromising quality With XRT many materials can be recognized through the density of the material and consequently separated. The differences between heavy metals (higher molecular density) and light metals can be recognized and sorted in a well-fractionated material flow. Therefore, the use of XRT is well suited for a Zorba product, for example . But what about the production waste in the aluminum sector ? Using XRT, slight differences between aluminum alloys can be recognized by recognizing denser molecules of elements such as Cu , Zn , Ni , Mn etc. The quality of the recognition is not sufficient for a clean separation and compromises have to be accepted very often. XRF is the more suitable form of technology for sorting aluminum alloys. To put it simply: XRF (X-Ray Fluorescence) is based on the spectroscopic analysis of existing elements from the periodic system. Based on the spectrum of the material sample is the composition of the elements determined qualitatively. This principle is used in X-ray fluorescence analysis and energy dispersion, among other things. Energy dispersive X-ray analysis is a measurement method of material analysis belonging to X-ray spectroscopy. The atoms in the sample are excited by an electron beam of a certain energy. These then emit X-rays with an energy specific to the respective element, the characteristic X-rays . This radiation provides information about the elemental composition of the sample. In contrast to the XRT method, the X-rays are reflected and collected and analyzed by the sensors. From the information obtained, we learn the composition of the particle and then use this information for sorting. Not all elements with XRF are detected, however. If we look at the periodic system, we see the so-called ordinal numbers of the elements. With the XRF-EDX process, reliable calculations can only be made from ordinal number 18. This means that a detection of Mg, Al and Si, for example, is not really possible and therefore no reliable data can be collected. Elements such as Cr, Mn, Fe, Co, Ni, Cu, Zn, Br, Au, Ag, on the other hand, are recognized very well and a meaningful sorting of metals can be achieved here very precisely and with high throughputs. The information obtained is decisive for the sorting quality. XRT and XRF in use. A comparison: XRT: - Belt sorting machine - high conveying speed (3-4 m / s) - high throughput - Narrow & precise grain grid necessary - well suited for Zorba sorting - for P roductionsabfälle less suitable - Light-heavy (high density / low density) sorting - High energy consumption - High spare part costs - Large design Conclusion: XRT is well suited for sorting heavy (high density) from light metals (low density). Ex. Zorba : easy and accurate separation of heavy metals such as Cu , Zn , brass, lead and stainless steel. XRF: - belt or slide machine - Lower conveying speed (2-3 m / s) - Lower throughput per working meter - Independent of the grain grid - Exact material analysis - Versatile, for mixed shredder fractions as well as for production waste - Lower energy consumption - Low spare parts costs - Compact design When using XRF, the individual elements can be based very precisely into light and heavy metals based on the sorting criteria set in the sorting software, regardless of grain size and grain grid. In addition, XRF enables the detection of metal alloys. In this way, differences between individual heavy metals such as copper, brass, bronze or zinc, for example, can be recognized, which can be important for the quality of a Zurik fraction. Let us take zinc as an example: In addition to free zinc particles you can also see the zinc content in an aluminum alloy. For the actual sorting, alloys can also be included in the sorting decision. When sorting Zorba material, we see that XRT can sort heavy metals very well and with a high throughput. The XRF technology can be used equally well for this sorting task and can also be used to further process Zorba or Zurik heavy metals in a second sorting step, depending on the requirements for the end product. With the help of XRF technology, nuanced sorting can be carried out, whereby an increase in the value of the material flows can be achieved. This can make sense for companies and better cover today's sales strategy and those in the future. In fact, there are no suppliers of both technologies and the manufacturers understandably always recommend their own technology. The customer is left to his own choice and should make the right purchase decision based on their sorting task and corporate strategy. The best solution for your aluminum sorting is the one that best covers both your technical and economic requirements.April 6, 2020

June 19, 2019

For upgrading smaller material quantities, the company Sense2Sort has developed “Plug ‘n Sort”-sorters based on different sensor technologies. This sorter offers great new opportunities. Get in touch and get the idea behind it. info@sense2sort.com Image S2S Plug`n Sort Opti-Sense Image S2S Plug`n Sort Opti-Sense

Image S2S Plug`n Sort Opti-Sense

June 19, 2019

Sorting and Recycling: Improved sorting qualities required Nothing new - the sorting of recycled material has become more important in the past, but this issue has gained even more importance as Asia is finally closing their doors to poorly recycled material streams coming from the rest of the world. Those companies dealing with the recovery and separation of resources in Europe and the rest of our western world, are now forced – also by politics – to handle this situation and improve recycling qualities by sorting much further than before. Increased sorting earns you money The separation of our recycled metals for example, can be done much better; our sorting technologies are able to reach the higher purities and better recovery rates, which are needed to have a short ROI and to earn good money on the final products. Outstanding sorting technolgies for any sorting requirement, even alloys

Input sample: Cu-Al 1-5mm

S2S Fines sorting: Cu >99%

S2S Fines sorting: AL >9

December 12, 2018

'Tis the season to wish one another joy and love and peace. These are our wishes for you, Merry Christmas our dear customers, partners & friends, may you enjoy this special season. Merry Christmas to everyone and everywhere.October 8, 2018

Opportunitites for SMEs. Sales markets for reclaimed and recycled metals change again and again, as do the associated sorting trends. The marketing of metals through small and medium-sized recycling companies is under pressure. Mostly, SMEs are looking for solutions to further optimize their source material flows without much effort or rebuilding. This applies to the metal recycler in the automotive sector, as well as to the WEEE recyclers or others who trade in recycled metals. Improving the material quality helps to increase the selling price again. In this article, we concentrate on the non-ferrous metals after the crushers, i.e. on the light and heavy metals such as aluminium, magnesium, zinc, copper, lead and stainless steel in a changed recycling world where China bans material fractions that were welcome before. In the US new tariffs have been imposed this year to impact the steel and aluminium industries. Consequently, sales markets have reduced as territories have closed their doors to inferior material qualities, or changed economically. With the sales markets getting geographically smaller, and thus the supply getting bigger, recyclers have to deal with further price reduction. Improving the material quality helps to increase the selling price again. The situation has changed: Need to upgrade Al sorting to avoid penalties for low material quality. Opportunities for SMEs. Shredder Residue, ZORBA, ZURIK: Let us look at how sorting quality can be improved cost efficiently by SME recyclers with different investment opportunities, because sorting better requires some investments. Todays recycling facility applies different sorting technologies behind shredder and magnet. To improve sorting efficiency in metal recycling, this is where we start to look into the process—focusing only on the sorting machines in this type of plant. The essential part of this material stream called shredder residue, does not contain too many metallic components, only 5-10% is metal. These are sorted out with the first sorting step, the eddy current separators (ECS). Here, the ECS produces the so-called Zorba and Fluff material fractions. Improving ZORBA: This mixture of light and heavy nonferrous metals, is rich in Aluminium, but this Al fraction is contaminated by the heavy metals portion such as zinc, lead, copper, brass, bronze, and stainless steel, but also PCB’s (Printed Circuit Board). The first consideration is to separate the light fraction of cast and wrought Al alloys, with some Mg alloys, from the heavies. None of the consumers of lights or heavies value the present of the other. The contaminating metals cause price deductions and thus reduce the income of the recycler. Recyclers are faced with the need to upgrade their Al fraction to avoid penalties for low quality material. Zorba has several separation options because of different sorting opportunities. With our spectroscopy-based sorters like S2S XRF-Sense and S2S LIBS-Sense, all metal types and alloys can be analysed and sorted based on their elemental properties. Now the customer will indicate his interest in terms of required sorting qualities and material streams. For example, wrought and cast sorting and the separation of the heavies, to reduce the zinc content or recover all high Fe aluminium alloys. Zorba can be a “pure” aluminium fraction using XRF and LIBS sensor based sorting technologies. These technologies are also applied by secondary aluminium smelters directly to cost efficiently create smelt ready metal packages. The good news is, todays sorting technologies allow the automatic sortation according to their elemental composition, thus even alloys can be classified. For their part, secondary aluminium smelters are opting to buy lower-cost scrap and process it into melt-ready packages. This ‘greener’ process approach not only makes their raw material supply more predictable but also increases the margin on their final product. Construction material, beverage containers and, most recently, the explosive growth in aluminium usage in vehicle manufacturing are the driving forces behind this approach. Improving ZURIK: The other post Eddy Current Separator fraction is supposed to be the waste fraction, or Fluff; at least it was called so, for many years, until the induction sorter was introduced into the European Metal Recycling market end of the last century. There is still a lot of metals to be recovered in the Fluff material stream: mainly wires and plastic coated wires, stainless steel, PCBs and a minimum amount of other non-ferrous metals, that are missed by the ECS can be recovered with induction sorters such as our S2S Metal-Sense. This extraction mixture of metal containing material is called Zurik. This machine is used for two steps in the Zurik application. First step is the stainless steel separation followed by the second step, where all wires and other metals are sorted out. The rest fraction is free of metals (>99%). The first step is getting more and more importance since stainless steel is unwanted in the copper wire fraction. The stainless steel fraction will have parts of metal rich PCBs and big copper pieces, so a quality control is needed by hand sorting or by applying our S2S-RobotSense, to automate manual sorting easily. In addition to providing standard sorting solutions for improving sorted material qualities in recycling applications, it has been our passion to supply customized plant solutions, integrating existing sorting technologies at the customers yard and improve the process to more efficiency by redesigning the process to today’s standards, both economically and on a reduced footprint. Sense2Sort Toratecnica, S.L. has built and serviced sensor-based sorting machinery for recycling applications all over the world. Their classic product offering is based on common sorting technologies such as Induction, CCD, NIR, XRF, LIBS and combinations thereof. Sense2Sort has been a continuous innovator and its aim is the perfect closing of the recycling loop using latest material identification methods. Using their deep know-how and experience, Sense2Sort’s experts consult on new and existing concepts for plant improvement and sorting perfection, achieving the highest process profitability for their customers. S2S LIBS-Sense sorter for automatic sorting of bulk metals according to their elemental composition such as Aluminum alloys

S2S LIBS-Sense sorter for automatic sorting of bulk metals according to their elemental composition such as Aluminum alloys

S2S 6-Sense sorter for separation of up to 6 fractions in one run

Please contact us at info@sense2sort.com and

S2S 6-Sense sorter for separation of up to 6 fractions in one run

Please contact us at info@sense2sort.com and

May 17, 2018

We were interviewed by Metalface and like to share this with you. Learn some facts about our company and our history. Eric, please introduce how long you are working in this business? For more than 2 decades my company is developing, building and selling sorting machines. It all started at Mogensen GmbH & Co KG in Wedel, Germany close to Hamburg. Here I was happy to be selected to design the first color sorter machine at that time for Recycling applications, called MikroSort. We started with glass sorters and soon began metals sorting on post ECS material streams. Later as a shareholder and CEO at SSE GmbH and a member of the CommoDaS group we designed the first belt sorters for the metal recycling and sorting industry. We developed and introduced the Finder, SpectraSense, and CombiSense in the market with success, 6 years later the group was bought by Titech GmbH. Do you see some trends in the metal trading industry these days? Please share your thoughts. The trends in sorting I see today are mainly pushed by the automotive industry and China’s legislation for material import, the high demand of aluminium for cars and many different new aluminium alloys, are asking for new sorting solutions for these materials. Here the latest development of S2S LIBSense machines, where LIBS-technology is able to analyze the different elements of each material piece passing by the laser head and allows to use this information in real time to detect and separate the different alloys. In other words, with this technology, we are able to separate different aluminium alloys, such as 5000/ 6000 series for the automotive or any other metal, but also wrought from cast or magnesium from aluminium. Comparing today and beginning of your career, what are the main differences in the industry? This is a lot, in the nineties. Sorting technology at the metal recycling yard was with a magnet and the ECS (Eddy Current Separator). It was very difficult to convince the owners that they still lose a lot of valuable metals after the ECS, because it was standard and most of the yards made their money with Ferrous and were not focused on the nonferrous that much. It was the Induction Sorter we introduced to recover the lost metals such as Stainless steel and the copper wires from the ECS drops (ECS accept stream). In the beginning of this century, when we introduced the belt sorters, it became a standard very slowly to install an Induction sorter after every ECS. With this machine invention, we made a start to improve metal recovery worldwide, save more resources, introduce new material qualities as well as reducing waste and landfilling. Today we cannot live without those sensor-based sorting steps in our modern sorting plant and this will continue growing also in the next decennia’s since we still have so many ideas. Real-time metal prices everywhere? Download our free app, have access to all the metal prices and get notifications on your phone whenever a metal price has a sudden big change. info@sense2sort.com Sense the Difference.April 23, 2018

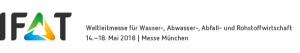

Sense2Sort at IFAT 2018 | 14.-18. Mai | Messe München, Germany. Your Sense2Sort sorting technology experts will be present at the upcoming IFAT show in Munich. Please contact us to schedule a meeting with Eric van Looy at +49 157 331 440 59 or Email us at evanlooy@sense2sort.com. We look forward to introducing our 2nd generation LIBS-Sense to you and discuss your state-of-the-art sorting options. Please get in touch and Sense the difference.

Sense2Sort at IFAT 2018 | 14.-18. Mai | Messe München, Germany. Your Sense2Sort sorting technology experts will be present at the upcoming IFAT show in Munich. Please contact us to schedule a meeting with Eric van Looy at +49 157 331 440 59 or Email us at evanlooy@sense2sort.com. We look forward to introducing our 2nd generation LIBS-Sense to you and discuss your state-of-the-art sorting options. Please get in touch and Sense the difference.

April 23, 2018

N-Expo 2018 in Tokyo Big Sight - Trade fair from 22.-25.May 2018.Sense2Sort was invited by EU Gateway to promote their technologies in Japan. Please contact us to arrange a meeting at the EU Pavillion at the N-Expo 2018 taking place at Tokio Big Sight Building. We are looking forward to meet you soon!

N-Expo 2018 in Tokyo Big Sight - Trade fair from 22.-25.May 2018.Sense2Sort was invited by EU Gateway to promote their technologies in Japan. Please contact us to arrange a meeting at the EU Pavillion at the N-Expo 2018 taking place at Tokio Big Sight Building. We are looking forward to meet you soon!

February 1, 2018

Here a picture of the S2S-LIBS-Sense, a 6-track sorting machine for the classification of Aluminium Automotive scrap. The machine is a production machine set up for an important aluminum producer located near Bonn, Germany. The machine has 6 tracks and can reach a capacity of 5 t/hr on a mid size aluminum fraction. The machine can also be installed for the sorting of Zorba, Heavies, all kinds of aluminum alloys (1000-7000 series), or wrought from cast material. Deutsche Übersetzung: Hier ist ein Bild der S2S-LIBS-Sense, einer 6-spurigen Sortiermaschine für die Klassifizierung von Aluminium-Automobilschrott. Die Produktionsmaschine wurde bei einem Aluminiumproduzenten in der Nähe von Bonn installiert. Die Maschine hat 6 Spuren und kann bei mittlerer Aluminiumfraktion eine Kapazität von 5 t/h erreichen. Die Maschine kann im Allgemeinen eingesetzt werden für die Sortierung von Zorba, von Schwermetallen oder jeder Art von Aluminiumlegierung (Serie 1000-7000) sowie für die Trennung von Guss- von Blechmaterial. Nederlands vertaaling: Hier een foto van de S2S-LIBS-Sense, een 6-track-sorteermachine voor de classificatie van Aluminium Automotive-schroot. Deze machine is een productiemachine die is geïnstalleerd bij een grote aluminiumproducent in de buurt van Bonn, Duitsland. De machine heeft 6 sporen en kan een capaciteit van 5 t/h bij een midelgroote aluminiumfractie bereiken. De machine kan o.a. Zorba, zware metalen of alle soorten van aluminiumlegeringen (1000-7000-serie) net als gewalst van gegoten materiaal sorteren. Sense the difference! Please visit our web site: www.sense2sort.com or Email us at info@sense2sort.comDecember 20, 2017

With special thanks to our premium and new customers we conclude a wonderful business year 2017 with lots of opportunities and successes for our company and products. We look forward to the new business year 2018 and invite you to share our Sense2Sort.

September 25, 2017

The latest technology innovation from Sense2Sort features ‘six-way sorting’ whereby the user can choose his or her sensor technology and sort up to six fractions in one pass cost-efficiently and within a small footprint. The sensor technologies that can be applied are: LIBS, XRF, induction, CCD, NIR and combinations thereof. Our technology experts will determine which sensor technologies fits best for solving your specific sorting task.

March 6, 2017

November 25, 2016

Sense2Sort has expanded their presence in the United States to better serve their customer base in the North American recycling market. Sense2Sort owners Eric van Looy and Eva Maria Gerosch are pleased to announce the foundation of a joined sister company in an equal partnership with Mr. Ulrich Schulte in New Jersey. The growing importance of the US American metal recyling market, and especially the Aluminum recycling market have asked for this step. Mr. Ulrich Schulte is announced president of Sense2Sort US, LLC. In close collaboration with Sense2Sort technology alliance partner Austin AI based in Texas, customers can now be served even more efficiently. Sense2Sort in the US feature customer test and machine production facility. Mr. Schulte is welcomed as a very valuable new member of the Sense2Sort team of recycling and machine technology experts. Mr. Ulrich Schulte and Mr. Eric van Looy/ Sense2Sort US LLC and Sense2Sort alliance partner Rick Comtois / Austin AI are looking forward to boost the US Aluminum recycling market and to bring alternatives and strong sorting technologies for improved plant procedures to their North American customers.

Sense2Sort is technology leader in automated spectroscopy for recycling application, with special focus on scrap aluminum processing. Latest LIBS and XRF sorting technologies allow automatic sortation of metals accoring to their elemental composition.

S2S XRF-Sense (X-Ray Fluorescence) machines are used for upgrading Zorba value by separating zinc, copper and Stainless Steel from scrap aluminum mix. Further application are meatball extraction (copper from ferrous shred); Zurik sortation (PCB`s, Stainless Steel, Copper, Aluminium); remove ceramic (High temp) glass and lead glass from cullet; extract pressure treated wood from C&D material)

S2S LIBS-Sense (Laser Induced Breakdown Spectroscopy) was designed to analyze and sort metals according to their chemical elements and thus improve sorting qualities of bulk material streams. This machine uses Laser Induced Breakdown Spectroscopy based Technology.

S2S-LIBS machines for Secondary Aluminum Smelters are used to improve incoming scrap lots to extract poisons like Magnesium, or produce a class of specific material. Examples are:

- Extraction of Magnesium metal from Twitch to reduce the need to chlorinate

- Separation of Cast Scrap Aluminium from Wrought Scrap Aluminium to reduce the need to adjust for the Silicon content

- Sortation of specific alloys used in the Automotive Industry, such as different material alloy series

Other applications are

- Ore and Mineral Sorting: Screen incoming feed stock for high value ore and analyze process material on contaminants and purify

Please contact us any time at info@sense2sort.com

Sorting makes Sense!

November 23, 2016

Leading in Automated Spectroscopy applied in metal recycling since 2006, Sense2Sort latest XRF and LIBS sorting technologies are the final step to a cradle-to-cradle process, resulting in huge energy savings and highly profitable recycling operations. IMRO Maschinenbau features a strong machine building history and range of magnet based sorting solutions.

Sense2Sort and IMRO have joined forces to boost Aluminum recycling with trendsetting and proven technologies and state-of-the-art plant designs. Take your chance and learn about true and exciting opportunities for your company. Meet us in hall 11 on booth 11K40 at Alu 2016 / Düsseldorf. To schedule a meeting contact us at info@sense2sort or call at +49 157 331 440 59.

We are looking forward to meet you in hall 11 on booth 11K40 at Alu 2016

Sorting makes Sense!

November 16, 2016

Automated spectroscopy is driving recycling and scrap sorting, helping to achieve historically-advanced levels of material recovery and reuse. Incorporation of X-ray fluorescence, laser induced breakdown spectroscopy and Terahertz imaging into modern sensor-sorter scrap processing lines is seen as key to closing the materials loop to the benefit of all parties involved.

October 11, 2016

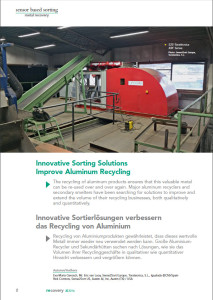

The recycling of aluminum products ensures that this valuable metal can be re-used over and over again. Major Aluminum Recyclers and Secondary Smelters have been searching for solutions to improve and extend the volume of their recycling businesses, both qualitatively and quantitatively. A major challenge has been the fact that a very high majority of scrap dealers do not supply their customers with scrap material that is ready to melt to their specifications. Thus, these secondary smelter customers must correct the incoming scrap as they melt it. These adjustments are costly - in terms of time, energy, materials, and throughput.

Sense2Sort alliance partners Austin AI (US based) and Toratecnica (Europe based) have launched an innovative sorting process technology that bridges the gap between the scrap dealer’s typical nondescript mix of scrap alloys and the smelter’s specific needs for furnace in-feed scrap. Now, for shredded scrap, it is possible to create a melt ready aluminum fraction from Twitch and Zorba. Now, for production scrap, it is possible to extract specific alloys from binary, tertiary, and quaternary mixes - such as 5XXX and 6XXX series - in a high purity and economically efficient manner!

September 13, 2016

Unsere Spezialisten für Sensortechnologien, Softwareentwicklungen und Maschinenbaudesign können auf mehr als 30 Jahre internationaler Erfahrung in der Fertigung von sensorgestützten Sortiermaschinen für die Schüttgutaufbereitung zurückgreifen, insbesondere für das Metallrecycling. Die enge Zusammenarbeit unserer Experten mit führenden Herstellern ermöglicht uns bei der Produktentwicklung die Berücksichtigung der neuesten technologischen Erkenntnisse. Dies garantiert stets verlässliche und hochqualitative Lösungen für alle Sortieraufgaben in der Schüttgutaufbereitung. Mittels automatisierter Spektroskopie ist es gelungen, auch Metall-Legierungen sortenrein zu trennen und so schmelzfertige Chargen herzustellen. Pionierarbeit, die überzeugt: Die Markteinführung von LIBS, XRF und Terahertz Technologien markiert eine neue Era im Recycling: Materialien ab 3mm Korngöße können heute auf elementarer bzw. molekularer Ebene effektiv und sortenrein getrennt werden. Sense2Sort folgt höchsten technologischen Standards um äußerste Qualitätsansprüche, Langlebigkeit und beste Sortierergebnisse zu ermöglichen: Unser Expertenteam erarbeitet Ihr Aufbereitungskonzept und liefert schlüsselfertige Lösungen bei Bedarf. Auch beraten unsere Experten herstellerunabhängig wie bestehende Sortierlinien energetisch effizient und leistungsstark optimiert werden können. Sorting makes Sense! info@sense2sort.comAugust 16, 2016

Sensor based sorting (SBS) equipment has become well established in recycling since their first introduction in the 1990’s, but now the time has come that SBS suppliers have nothing dramatically new to bring onto the market. Granted, there have been minor improvements in old technology’s performance, or there is re-packaging and other cosmetic changes to give the appearance of having something new. This is not the case for Sense2Sort. We have paradigm-shifting technology that advances the downstream sorting process to address the future needs of the scrap consumers.

We are proud to show up with a real and significant step forward. It has become possible to analyze a particle‘s elemental composition by chemical content. Since introducing our S2S XRF-Sense in 2006 for the first time, the XRF technology has been continually redesigned thereby increasing processing speed; improving sorting qualities; hardening components for maximum lifetime; and perfecting the operating software and processing algorithms. We are proud to offer our newest generation of S2S XRF-Sense to our customers. Users can truly benefit via raising their profitability in an eco-friendly and cost-efficient manner.

The XRF has marked the start of a new era in sorting and recycling, complimenting common sorting technologies and opening up new territories for scrap producers and consumers. It is a fact that XRF can increase scrap metal specificity following gross sorting methods such as float/sink or XRT.

However, XRF has one limited application and this is light metals. To address this, S2S introduces LIBS-based sensor sorting. LIBS outshines everything sensed so far and is a breakthrough in light metals identification and classification. Designed for difficult environments like material handling and recycling, S2S LIBS-Sense delivers precise readings of light metals and alloys which could not be automatically sorted before. This helps our customers to upgrade more of their product and raise profits.

The LIBS analyzers are designed to identify truly light elements (e.g. Li, B, Be, Na, Mg), and heavy metals simultaneously.

Taking the secondary smelting of aluminum as an example, S2S LIBS technology enables the classification of individual classes of wrought alloys like 1000 thru 7000 series according to their chemical composition. Contaminants like copper, brass or ferrous or even plastics can be separated easily. Separating alloys gives way to increased profits and reduced cost for operators and smelters.

Our expertise in SBS goes back to the start of it. We are true experts in this business and offer you complete systems that separate multiple fractions in one pass. With our high frequency lasers there is no need for any pre-cleaning of the material surface and we realize a thruput of 2-5t/hour. Sorting of scrap alloys with minor alloying elements based on 0.5% difference has been proven. Additionally, true sorting of wrought and cast Al alloys based on the Si chemistry is another strong application.

As leaders, we are not resting on our achievements. S2S is continually working and we will be at the forefront with more, new, recycling technologies in the future. Welcome to the new way of recycling metals--delivering a sorted product that is ready to melt. This makes sense.

info@sense2sort.com

June 25, 2016

In the recent past, sorting Aluminum alloys by means of XRT (X-ray-Transmission) technology has been tried. However, this expensive sensor technology (based on the physical property of material density) is not precise enough for specific alloy sorting. Additionally, extra material preparation stages like sizing for XRT sorting is costly and time consuming. Sorting with XRT has demonstrated to be cost inefficient and yielding poor product quality when used beyond the stage of rough sorting light and heavy metal alloys commonly found in shredder scrap.

XRT sorting technologies alone are not good enough for most aluminum recycling applications. Chemistry is the key.

The scrap processor to scrap consumer business link is therefore in need of a better bridge by which they may conduct their trade. In the Sense2Sort model, the XRT approach is thus followed by XRF (X-Ray Fluorescence) technique. Using the XRF sensor technology, aluminum alloys can be classified cost efficiently, at a high quality, and at an economically viable throughput performance. Different than XRT, which results merely in black white imaging as sorting criteria, XRF sensing allows the definition of plain material composition according to the atomic elements table. XRF, and its partner technology in Sense2Sort’s first-of-its-kind scrap metal processing line, LIBS, are elemental analyzers that use the chemistry of the target material for identifying or sorting criteria. For example, the XRF technology has proven usage for the scrap metal processors in sorting their Zorba und Zurik. XRF extracts Zn, Cu, Ni, Fe, etc., from the Zorba; and extract only PCB’s or Cu from Zurik material.

Is this interesting for you? Are you coming to IFAT? Let us meet and discuss your sorting opportunities.Please contact at info@sense2sort.com

May 19, 2016

The recycling of aluminum products ensures that this valuable metal can be re-used over and over again. Major aluminum recyclers and secondary smelters have been searching for solutions to improve and extend the volume of their recycling businesses, both qualitatively and quantitatively.

February 23, 2016

The following text (see web link) shows why having the ability to extract Mg will become more and more important:

http://www.wsj.com/articles/casting-the-future-of-lighter-vehicles-1455892867

February 9, 2016

Sense2Sort alliance partners Austin AI (US based) and Toratecnica (Europe based) have launched an innovative sorting process technology that bridges the gap between the scrap dealer’s typical nondescript mix of scrap alloys and the smelter’s specific needs for furnace in-feed scrap. Now, for shredded scrap, it is possible to create a melt ready aluminum fraction from Twitch and Zorba. Now, for production scrap, it is possible to extract specific alloys from binary, tertiary, and quaternary mixes in a high purity and economically efficient manner! Finally, one can achieve “closing the loop” in aluminum recycling to the point of ultimate alloy specificity. As an example, alloys of the 5xxx and 6xxx series can be sorted. This is done with LIBS (Laser Induced Breakdown Spectroscopy). Several key applications are the sorting of Aluminum extruded parts (typically 6XXX series) and automotive recycling applications (where 5XXX series alloys are common). Latest XRF and LIBS sorting technologies are the final step to a cradle-to-cradle process, resulting in huge energy savings and highly profitable recycling operations. For complete Aluminum recycling solutions, Sense2Sort has developed and engineered fully automated dry process including XRF and LIBS Technology. Sense2Sort Solutions include a variety of sorting technologies, such as XRF and XRT, CCD, Induction, and combinations thereof as well as peripheral devices such as magnets, screens, feeders and engineering.December 10, 2015

Spanish and American sorting technology firms will offer combined systems to metals and plastics recyclers. Sorting technology firms Sense2Sort/Toratecnica S.L., Igualada, Spain, and Austin AI Inc., Austin, Texas, have announced they “have joined forces to provide the marketplace with the most advanced and most comprehensive product offering possible.” The two companies say their alliance has been spurred by changes in the marketplace requiring shredded nonferrous metals products with purer chemistry than what is found in the zorba grade. “Everyone is aware of the need to recover more metals with more specificity from zorba and other nonferrous scrap metal streams, such as e-scrap and bottom ash,” Sense2Sort and Austin AI write in the news release announcing their alliance. “It is clear that the future is dim for those who wish to simply sell zorba as is and [who] rely on end users to perform the final cleanup stages either premelt or in-melt,” the companies continue. “This change is happening now in the secondary aluminum smelting industry as the market for aluminum scrap is much stronger than for that of zorba.” Austin AI and Sense2Sort say that for the past 15 years they “have been leading the world in sensor sorter technology development.” The combined product lines of the two companies comprise an array of devices and systems, including X-ray fluorescence (XRF), X-ray transmission (XRT), laser-induced breakdown spectroscopy (LIBS), near infrared (NIR), terahertz (THZ)-based black plastics sorting, induction sensor sorting (ISS), CCD (charge-coupled device) color sorting and robot picking technology. The two companies say they also will work with supply partners to “provide complete, turnkey process lines” that can include conveyors, hoppers, shredders, sieves, magnets, eddy current separators, compressed air devices and dust control technology. “As renowned trendsetters in sensor-based sorting, we specialize in compacting sorting lines and greatly raising plant efficiency for our customers,” states the joint Sense2Sort and Austin AI press release. “We are proud of presenting innovative sorting plant solutions that create a maximum of value for our customers. Additional information about the product lines of both companies can be found at www.sense2sort.com and at www.austinai.com. Published November 23, 2015 in Recycling TodaySeptember 4, 2015

Sense2Sort-Toratècnica of Spain has extensively researched traditional sorting procedures and identified a need to rethink sorting methods to meet emerging requirements and opportunities. In the future, recyclers and processors will be asked to recover ever more material – so the status quo will not be good enough.

August 20, 2015

Interview to Eric van Looy of Toratecnica By Martijn Reintjes.

Recycling International Magazine, read more online

April 8, 2015

Today, two Specialists in the development of sensor based sorting solutions have joined forces to create The Team and collectively present their technologies to the world's recycling market. Never before has there been such a one-stop shopping opportunity for the Intelligent Customer who seeks to be a leader in the use of advanced sortation and separation systems. With a history of providing successful installations in a wide variety of applications; and the combination of experience in delivering industrially robust systems with novel sensor development; The Team ensures that our clients are always ahead of their competition-Working Smart, not just hard. And the undeniable leaders in introducing the world tot the next generation of sorting technology, The Team also has the ability to custom fit specialized systems into your unique process. No more "One Size fits All" for the Discerning Customer. We have engineered complete process lines for a variety of recycling applications. The Team presents themselves at the IARC Congress in Berlin from 25-27th April 2015: From Toratecnica Spain, will answer your questions.

Ask for Robotic Meatball Picking

Stainless Steel Sorting

Zurik Sorting

Melt Specific Package Technology

And any other sorting requirement you may have.

15TH INTERNATIONAL AUTOMOBILE RECYCLING CONGRESS IARC 2015

March 25 – 27, 2015, Berlin, Germany

The congress is a platform to exchange the latest information, to meet your business partners and to get easy access to new potential clients.

And can be met at the ISRI show in Vancouver:

From Toratecnica Spain, will answer your questions.

Ask for Robotic Meatball Picking

Stainless Steel Sorting

Zurik Sorting

Melt Specific Package Technology

And any other sorting requirement you may have.

15TH INTERNATIONAL AUTOMOBILE RECYCLING CONGRESS IARC 2015

March 25 – 27, 2015, Berlin, Germany

The congress is a platform to exchange the latest information, to meet your business partners and to get easy access to new potential clients.

And can be met at the ISRI show in Vancouver:

Toratecnica, S.L. will be represented by Mr. Comtois from Austin, AI during this years ISRI show in Vancouver, Canada. Please contact us to set up your meeting schedule.

For more information: contact us

Toratecnica, S.L. will be represented by Mr. Comtois from Austin, AI during this years ISRI show in Vancouver, Canada. Please contact us to set up your meeting schedule.

For more information: contact us

March 26, 2015

Toratecnica presents the next generation of meatball sorting. This sensor based Intelligent Robot Sorter is the first of its kínd that is able to detect copper and pick it automatically from your ferrous shred stream. Depending on the sensor fusion configuration, other material (tires, rags) can also be detected and picked. This latest trendsetting sorting device can replace your manual sorting without reengineering and rebuilding your picking station. Because Toratec Sorting makes Sense! For more information: contact usApril 2, 2015

Toratecnica has launched their new Homepage on www.sense2sort.com. We like to invite you to have a look and enjoy travelling through our new world of recycling. For any enquiries, please contact usOctober 30, 2014

Toratecnica S2STowerSense Solutions convince by more sorting quality, more throughput, less conveyors, little footprint, less invest, ... Toratecnica has redesigned their unique S2S Tower Sense Concept. In essence the material is sorted from top to bottom (and not in a line as it is usually done) aiming at a more efficient sorting process. This way, material is fed into the system once and the material flow is perfectly spread in the course of its way through the sorting tower. This is a prerequisite for sorting: optimum distribution of the material pieces on the belt for best possible detection and sorting subsequently. By sorting online and downwards, the sorting systems applied detect and sort to the max under best conditions. The Toratecnica ToraTower can be equiped according to the respective material and sorting tasks. For more information: contact usSeptember 17, 2014

Toratecnica has developed a coin sorter used to sort international coins found in recycling. Some recycling companies find it more profitable to sort the coins found after the shredder than selling them as NF metals. For those interested please contact us for more information: contact usAugust 22, 2014

ToraRobotics belongs to the ToraGroup of companies and focuses on robotic picking solutions to automate manual sorting which still takes place extensively in all recycling branches and all over the world. Hand sorting waste is unhealthy, bears danger of injuries, is very tiring and badly paid. The technologic advantage to manual sorting is clear. The operator benefits from steady sorting results 24/7, calculable sorting efficiency and higher profits, and –of course- low energy consumption. For more information: contact usJuly 23, 2014

Toratecnica has developed a machine which sorts the material stream in one run into different fractions: downsizes a sorting line to one machine only! Technology innovations are needed to meet future recycling targets. Our high quality technology is based on 20 years of expertise in the design and production of sensor based sorting technologies. To sort efficiently, we choose the technology you require to meet your sorting demands reliably. We work with RGB, Induction, NIR, XRT, Laser, Combinations and Sensor Fusion as our latest development. This Sense2Sort product innovation substitutes 1 sorting line by one sorting machine with multiple outlets. For more information: contact us